High-speed network nemi Link 2400

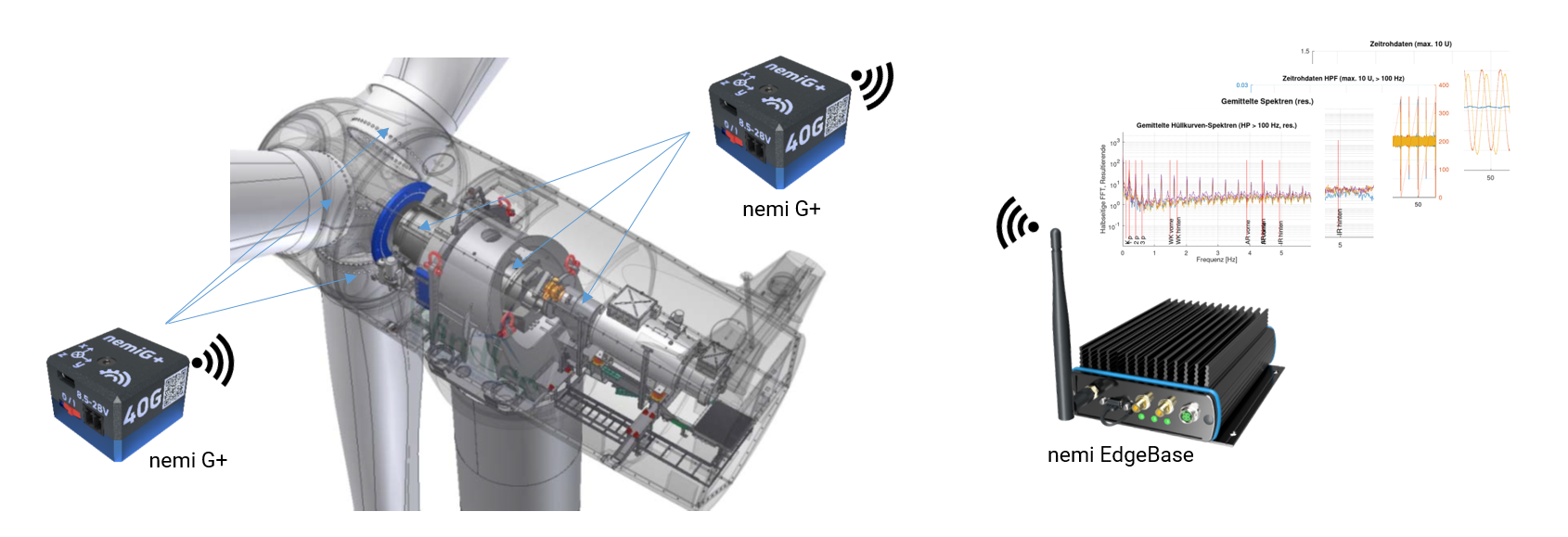

Our proprietary wireless technology nemi Link 2400 is a battery-powered sensor network in the 2.4 GHz frequency band with star topology. This high-speed network enables the reliable transmission of data at high sampling rates. Whether rotating, moving or stationary applications, short or long ranges, high or low sampling rates, long or short battery life, there are countless applications for wireless sensors and the requirements are diverse. One example is force, torque and rotation angle measurements at various positions on the rotor shaft of a wind turbine.

Even the standard settings of our nemi Link 2400 high-speed wireless technology meet the requirements of many applications and enable quick setup and ease of use. To optimize the measurements of your use case, nemi Link 2400 offers you the possibility to adjust the number of sensor nodes per radio channel and the radio speed of your nemi Link 2400. This way, you achieve your perfect balance between range, data rate and runtimes for each application.

This table provides an overview of the setting options for the nemi Link 2400 network:

| 2 Mbit/s |

indoor: 20 m

urban: 50 m

theoretical: 300 m

|

36 kHz* |

Highest energy efficiency -> longest battery runtimes |

| 1 Mbit/s |

indoor: 50 m

urban: 125 m

theoretical: 750 m

|

15 khz* |

|

| 500 kbit/s |

indoor: 90 m

urban: 225 m

theoretical: 1800 m

|

8 kHz* |

|

| 125 kbit/s |

indoor: 140 m

urban: 350 m

theoretical: 2100 m

|

3 kHz* |

Lowest energy efficiency -> shorter battery runtimes |

* The values in this table are standardized to a resolution of 24 bit. Not all sensor nodes have the same resolution. You can calculate the exact total sampling rate for your application in the Configuration Tool.

Use our nemi Link 2400 configuration tool to find out how you can optimize the nemi Link 2400 settings for your application. Lois Jacobs explains the details in the following video.

Long Range Network nemi Link 868

The nemi Link 868 long range network is a wireless, battery-powered sensor network in the 868 MHz frequency band with star topology. It enables the reliable transmission of data at low sampling rates over long distances and with years of battery life. One example is the crack width measurement on a 500 meter long freeway bridge with 30 sensor nodes.

|

|

| Sensor nodes per gateway |

30

|

| Radio range |

up to 1000 meter

|

| Radio frequency |

868 MHz band

|

| Max. sum sampling rate at 24 bits per sample |

ca. 200 Hz

|

| Usual battery runtimes of the sensor nodes* |

> 5 years

|

| Associated gateway |

nemi WAMS Bridge - providing data via energy-efficient 4G NB IoT cellular connection

|

* At a usual duty cycle of 1 - 10 % (ratio of system on / data acquisition and transmission to sleep state). Exact run times can be accurately calculated, predicted and guaranteed for given sampling interval and given environmental conditions.

Hardware

nemione® products enable measurements with a wide variety of sensors. In the following graphic you will find an exemplary overview of sensor types that are integrated on the sensor nodes or can be connected to the sensor nodes:

Sensor types

Industrial standard sensors with voltage output (0 - 10 V)

Digital sensors with all typical voltage levels

(5, 12, 24 V)

Wheatstone bridge sensors (e.g. strain gauges, pressure sensors, etc.)

Potentiometer sensors / Distance sensors

Thermocouple (e. g. Type K) and thermistors

Resistance sensors with constant current supply (e.g. resistance thermometers PT100 / PT1000)

High-resolution, triaxial, capacitive MEMS accelerometers

IMU for measuring accelerations and rotation rates in and around 3 axes each (ACC, GYR)

Displacement sensors for distance measurement

GPS modules for localization

Rotation angle-dependent display of data in the rotating system

In addition to the main sensor (e.g. accelerometer, strain gauge,...) a 9 DoF IMU (3-axis accelerometer, gyrometer and magnetometer) is also installed on nemione® sensor nodes. This allows triaxial accelerations, rotation rates and magnetic fields to be measured synchronously with the main sensor. In rotating applications, the angle of rotation can be calculated from this and the data from the main sensor can be displayed as a function of the angle of rotation.

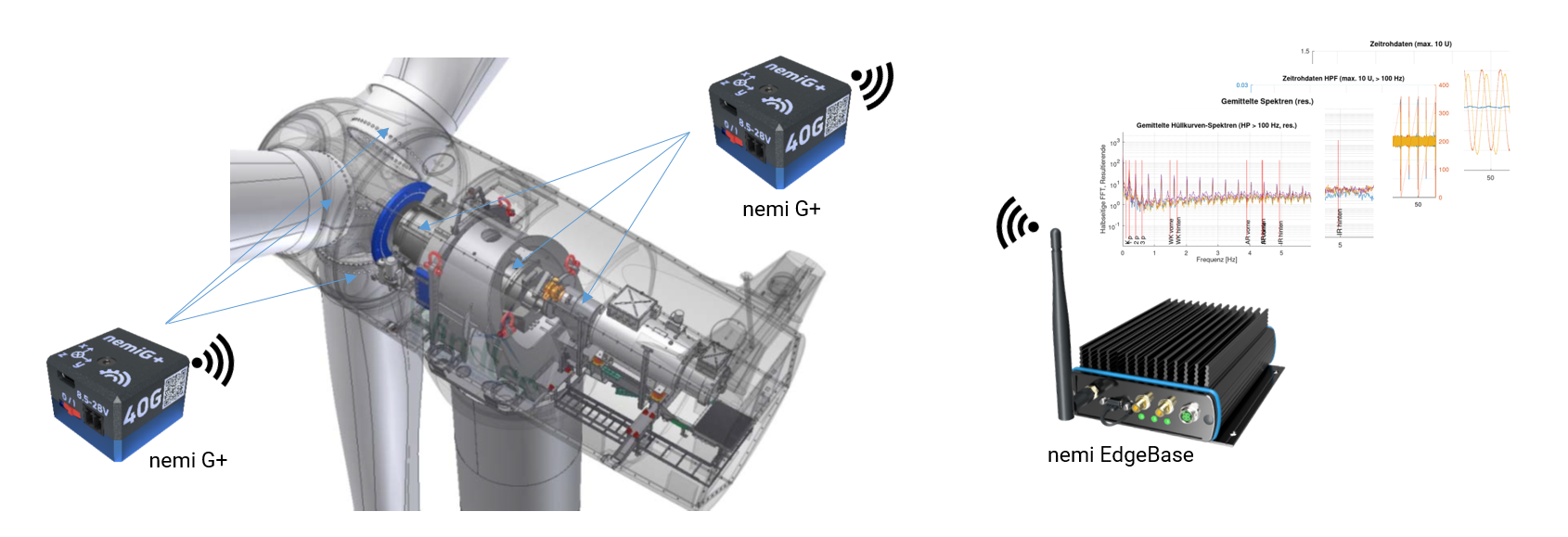

We show the advantages using the example of a wind turbine:

By combining angle of rotation and acceleration measurements, vibrations and oscillations of components such as rotor blades, main gearbox, main shaft and main bearing can be analyzed in the angle of rotation. By recording the vibrations over the angle of rotation and averaging over long periods of time, unbeatable data quality and clean spectra are obtained, even if the speed changes significantly during the measurement. The measurements can then be analyzed to detect possible irregularities or anomalies and take action for maintenance or repair before serious damage or failure occurs.

Data analysis

nemione® offers hardware and software from a single source. The data analyses can be performed directly in the sensor or in the gateway (so-called edge analytics) as well as on the server. The great advantage of edge analytics is the reduction of the transmitted data to the essentials ("smart data"). This reduces storage space on the server and increases battery runtimes.

Your data remains your capital: We do not rely on big cloud providers but can keep the data in your IT ecosystem. Alternatively, you can rely on our nemione cloud solutions - hosted in the European Union.

Based on our knowledge from a multitude of previous projects, we have developed algorithms for data evaluation to generate maximum added value for our customers. We gladly advise you on this. In addition to our existing algorithms we create individualized scripts upon request.

Data analysis

Data pre-evaluation in the sensor node / in the gateway (so-called edge analytics) with customized algorithms according to the latest state of science and technology

Data re-evaluation on the server (on-premises or hosted by nemione in the European Union) with customized algorithms according to the latest state of science and technology

Data storage in databases; raw data always transparently accessible to the customer

Data display in clear and customizable dashboards

Additional alerting and notifications via mail and / or SMS