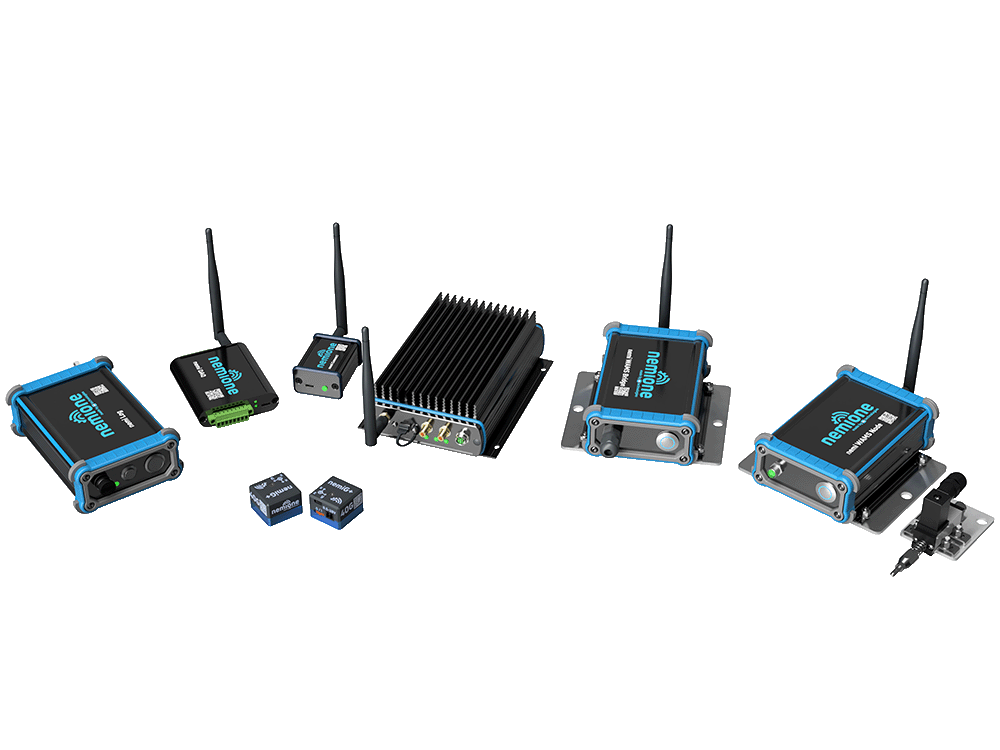

Products

nemi Link 2400 sensor nodes

nemi G+

Small, wireless sensor for measuring accelerations, vibrations and rotation rates

nemi G+ nano

Tiny, Wireless Sensor with Energy Harvesting Module for Measuring Accelerations, Vibrations and Rotation Rates

nemi DAQ

Wireless Multi Sensor for Monitoring Strains, Forces, Displacements and much more

nemi DAQ nano

Tiny Wireless Multi Sensor with Energy Harvesting Module for Measuring and Monitoring Strains, Forces, Displacements and much more

nemi Link 2400 receiver modules

nemi Connect

Small data receiver for direct connection to the PC via USB-C

nemi Log (+ cellular)

Battery Powered Wireless Data Logger with Integrated Sensors and cellular option

nemi EdgeBase

4G-Gateway with Linux operating system and edge computing capabilities

nemi Link 868

Technology

Application

Use Cases